Cheap ribbons can kill your uptime

Your choice of thermal transfer ribbon can have major implications for both your customers and operations team in terms of legislative compliance, print quality and equipment reliability. A poor choice risks unreadable codes/print, frequent line stoppages and expensive repair bills so correctly matching a ribbon to your needs is imperative.

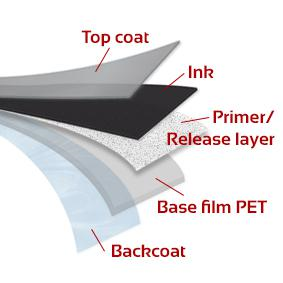

In simple terms, a thermal transfer ribbon consists of a plastic backing material coated on one side with ink. In reality, there can be several layers added to this simple configuration to enhance the performance of the ribbon. Most in-line thermal transfer applications utilise either Wax/Resin or Resin only coatings to deliver the desired print quality and printer performance.

Wax/Resin ribbons incorporate a blend of wax and resin in the ink coating that allows a good blend of print speed, scratch resistance and quality. These ribbons are generally well suited to a wide variety of applications and have the widest variety of colours to choose from.

Pure Resin ribbons offer even better scratch and smudge resistance as well as higher temperature resistance and print quality but this improved performance comes at the cost of lower speed operation and higher roll price.

Whether you need wax/resin or resin, choosing a quality ribbon that includes a suitable backcoat layer is essential because it is the backcoat layer that provides the majority of protection for your printer’s printhead. Problems such as high printhead wear due to lack of lubrication or printhead failure due to static discharge are common when cheap, poorly manufactured ribbon is used.

At Uptime technologies, all our ribbons are produced by globally recognised manufacturers who employ the latest technologies to ensure you achieve excellent results at the optimum total cost of ownership.

For more information on our range of thermal transfer ribbons click here